6061 vs. 6063 Aluminum: Choosing the Right Alloy for Your Application

When it comes to aluminum alloys, 6061 and 6063 are two of the most commonly used grades â€� especially in structural, architectural, and industrial applications. While both belong to the 6000 series and share many similarities, there are key differences that determine which alloy is best suited for your project.Ìý

Understanding how these alloys differ in terms of composition, strength, corrosion resistance, formability, and end-use can help you make an informed material choice that supports your performance and budget goals.Ìý

Chemical Composition and PropertiesÌý

Both 6061 and 6063 are aluminum-magnesium-silicon alloys, but they vary slightly in their composition, which affects their mechanical properties:Ìý

AGÕæÈ˹ú¼ÊÌü higher magnesium and copper content in 6061 results in greater strength and hardness, while 6063's lower alloying content enhances its surface finish and makes it easier to extrude into complex shapes.Ìý

Mechanical Strength and PerformanceÌý

6061 aluminum is known for its superior strength and structural integrity. It offers a high strength-to-weight ratio and excellent resistance to fatigue, making it an ideal choice for applications requiring durability under load.Ìý

6063, by comparison, has slightly lower mechanical strength but is more than sufficient for applications where formability, aesthetic finish, or lightweight structures are the priority.Ìý

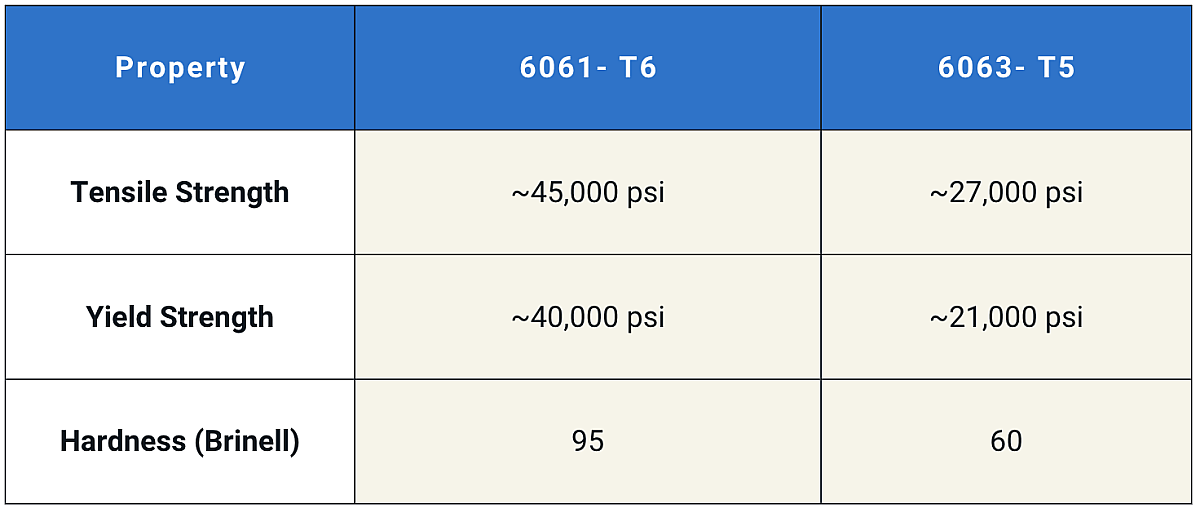

Typical Mechanical Properties:Ìý

Corrosion Resistance and WeldabilityÌý

Both alloys perform well in corrosion resistance, especially in outdoor or marine environments. However, 6063 may edge out slightly in anodizing applications due to its smoother finish and more uniform surface. That makes it a go-to choice for visible architectural components like door frames, windows, and trim.Ìý

Both 6061 and 6063 offer excellent weldability, but 6061 can experience slight strength reductions in the heat-affected zones of welds. Post-weld heat treatment can help recover mechanical properties when needed.Ìý

Formability and MachinabilityÌý

- 6061: Better suited for machining and structural fabrication. It responds well to milling, drilling, and tapping, making it a favorite in the aerospace, automotive, and heavy equipment sectors.

- 6063: Preferred for complex extrusions with tight tolerances and smooth surfaces. Its superior formability makes it easier to shape without compromising surface finish.Ìý

6061 Aluminum Common Applications:Ìý

- Structural components

- Aerospace and automotive parts

- Marine fittings

- Heavy-duty pipelines

- Truck frames and trailersÌý

6063 Aluminum Common Applications:Ìý

- Architectural extrusions

- Window and door frames

- Decorative trims

- Railings and fences

- Signage and display systemsÌý

Which Aluminum Alloy Should You Choose?Ìý

When strength and machinability are top priorities, 6061 is often the better choice. If your project demands a smooth surface, tight tolerances, or complex extrusions—especially in architectural or consumer-facing applications, 6063 is likely the ideal alloy.Ìý

Mill Steel Company: Your Trusted Metals SupplierÌý

At Mill Steel Company, we offer an extensive inventory of aluminum products in a wide range of sizes, finishes, and tempers. Whether you need material for large-scale manufacturing or precision extrusions, we provide the quality and consistency your operations demand.Ìý

With nationwide distribution and responsive customer support, we help keep your supply chain running efficiently. Need help selecting the right aluminum alloy for your application? Our experienced team is here to guide you every step of the way.Ìý

Request a quote now or contact us to speak with one of our aluminum experts.Ìý